Cutting

LASER AND WATER JET CUTTING

Laser and water jet cutting are computer controlled processes that enable us to cut materials,

even thick materials, without inducing stresses and burrs.

Complex shapes can be cut with both processes without tooling.

SHEAR CUTTING

Manufacturing by shear cutting guarantees straight-line cutting of the material between two blades (shear principle).

Registration is provided by:

- guides,

- adjustable stops,

- mechanical locations,

- optical sights.

GUILLOTINE CUTTING

Guillotine cutting is a process that consists of cutting on a press with a custom made tool.

This tool is made according to all outer and opening shapes of the piece to obtain.

Various processes can be combined to this tool (bending, stamping, embossing).

Registration is provided by stops, optical sights or locations.

PRESS CUTTING

Press cutting is done on a press with a custom made punch and die tool, created

in compliance with all outer and opening shapes required.

Various processes, like bending, stamping or embossing, can be combined to this tool.

Registration is provided by stops, optical sights or locations.

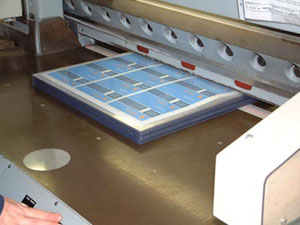

PLATEN PRESS CUTTING

The platen press cutting process consists in one unique operation of die cutting and/or kiss cutting of all openings and outer shapes, made with a steel rule die. This process can be done for single or several layers of material.

FLATBED CUTTING

Die cutting and/or kiss cutting by digital control of plastic films up to 500 µm. Cutting is done thanks to the use of blades, running following the plotter principle.

Software used: UNILET, EASYCUT.

For additional information,