Laser scribing

PROCEDURE

The Laser scribing process enables the engraving of many types

of materials to get customized products.

Etching by material ablation is obtained by focusing the energy on the surface which generates instant volatization of the material, and creates a print called: etching.

Laser marking by transforming the surface color is obtained by heating the material until its fusion point. This generates a surface color change.

Marking by removal of a material layer consists in using a multilayer material. The laser takes off one or several layers until it reaches the below layer that reveals its own color.

ADVANTAGES OF LASER SCRIBING

An indelible, high resolution print

High-speed, economical and indelible print. The process is simple with complete design freedom. The marking allows for small lettering. The process allows for the customisation of series parts: incremental numbering, bar code, etc.

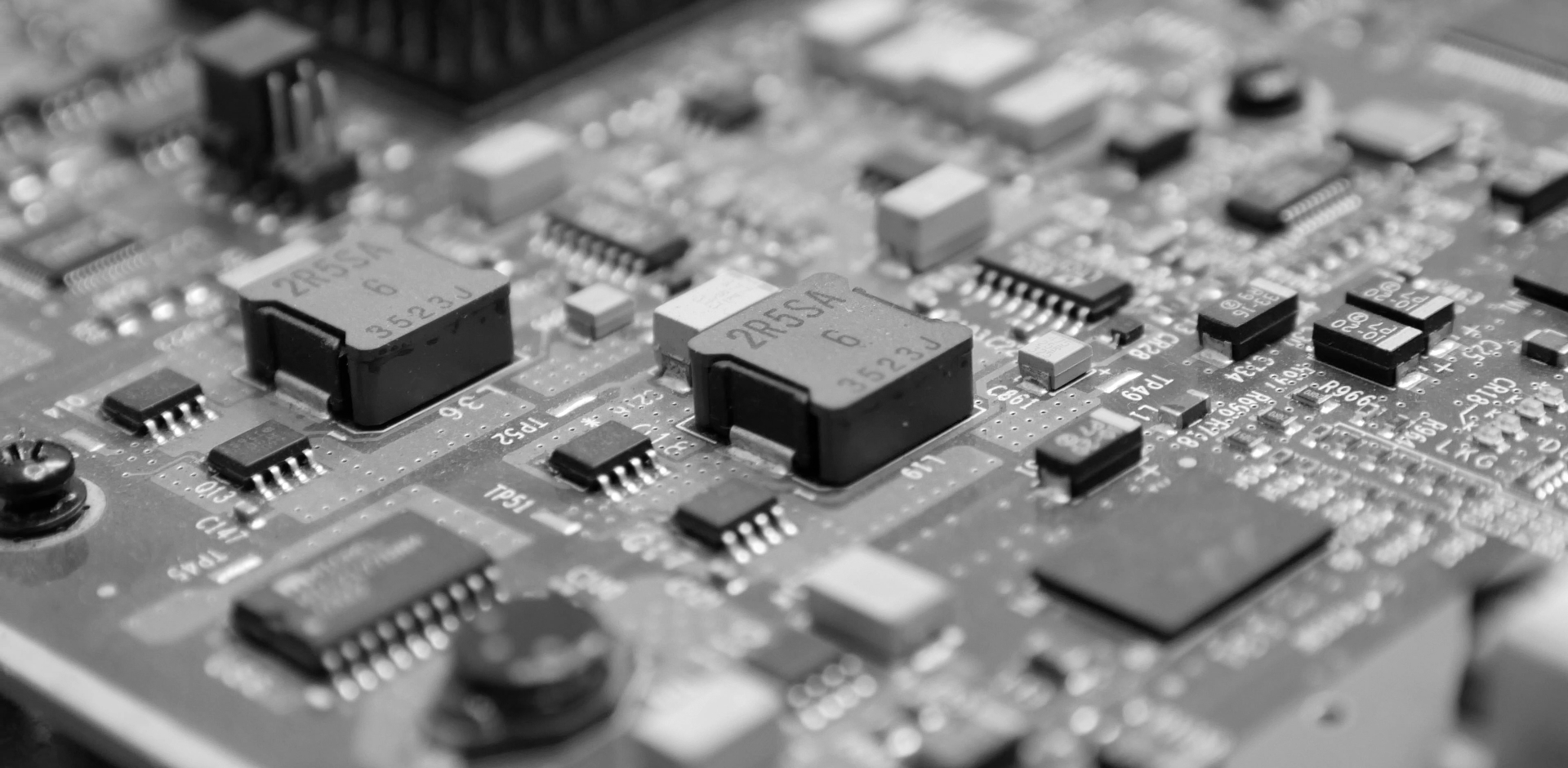

USES

Multiple uses

We offer marking on a wide variety of materials: metal and plastic. We have high production rates, from single pieces to complete sets.

For additional information,