Screen printing

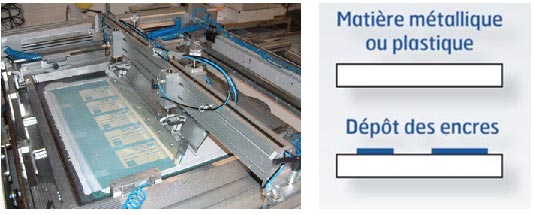

PROCEDURE

Stencil principle

Applying ink, one colour after another, through synthetic screens.

The screens are made by isolating images with a laser.

ADVANTAGES

Quality, speed, cost

A broad selection of inks in traditional colours or special effects: mirror, textured, etc.

A fast, cheap process.

Intense, durable solid colours, with good opacity.

APPLICATIONS

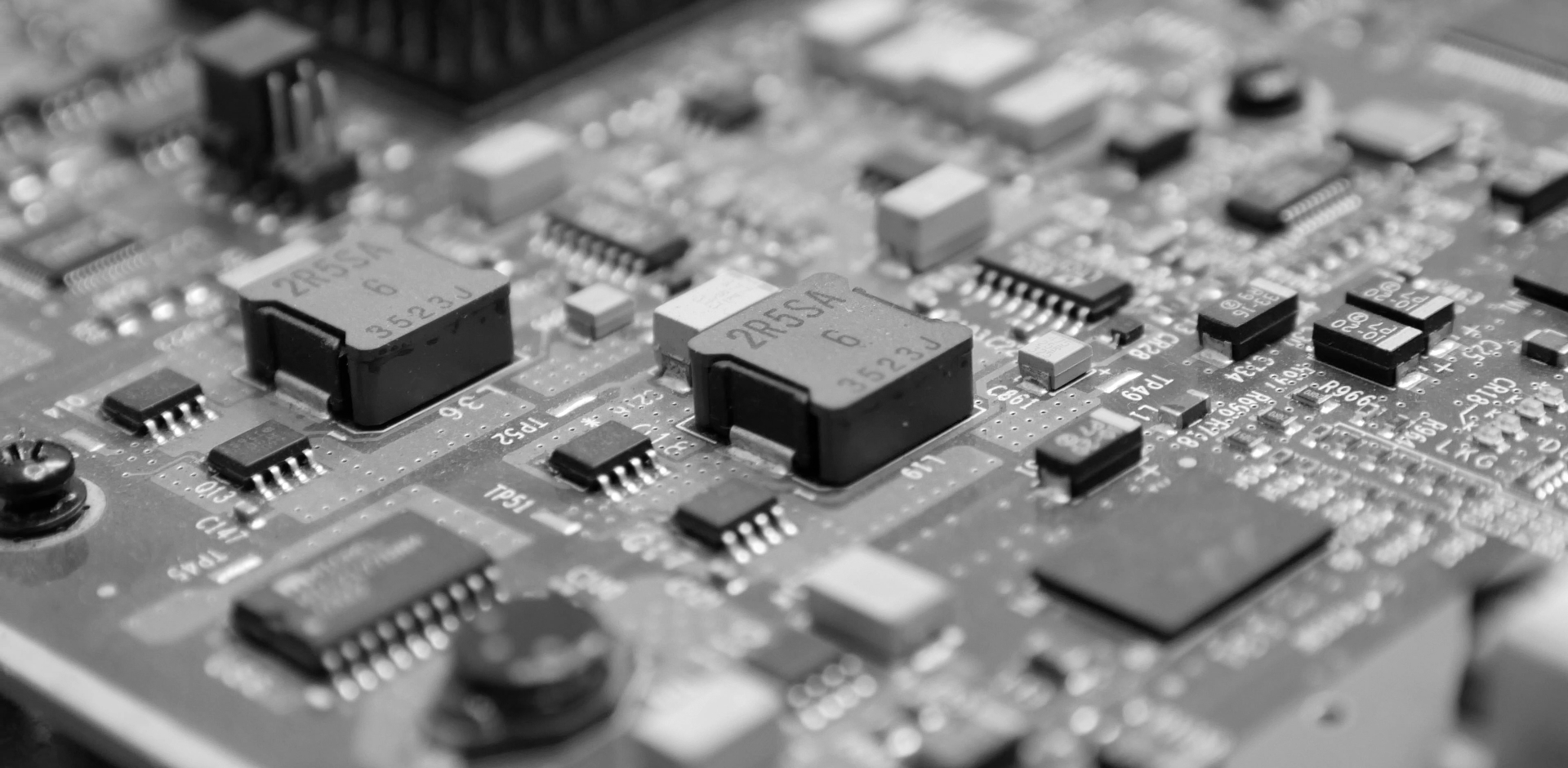

For all types of rigid media

Any flat surface, metal or plastic.

Reproduction of repetitive designs for medium and large production runs.

If ever there was an essential technique for our job, it would be screen printing!

Screen printing is a process in which an image is isolated on a taut canvas. The resulting “screen” has meshes for open and closed sections. The printing itself is carried out using a scraper that applies ink through openings in the canvas, transferring it to the material to be printed.

This apparent simplicity belies a profession and expertise that are in fact highly specialised. Indeed, depending on the desired result and appearance, each print run requires particular inks, mesh, and screen tension.