Barcode label

There are a range of metal and plastic based mediums that can be used for Barcode labels, each matching with specific operational requirements: Quick identification, simplified labelling, optimised stock control, resistance in harsh environments, longevity, etc.

Stock traceability and control

The leading French specialist in marking on plastic and metal labels for industrial applications, Martin Technology combines expertise, innovation and passion to transform and simplify your stock management and guarantee perfect traceability for goods and machines.

Our labelling solutions stand out thanks to their capacity to revolutionise stock management, guarantee an infallible traceability of products and equipment, and protect data. From this perspective, a barcode label is the ideal solution, acting as the link between physical products and advanced software applications.

Metal or plastic barcode labels

What is a barcode?

Barcodes are used in a large number of sectors and provide an identification method based on series of parallel lines of differing thickness that are used to represent information.

There are several types of barcodes, namely linear (1D: UPC, EAN, ITF, etc.) and two-dimensional (2D: QR Code, Datamatrix, etc.), each particularly suited for specific requirements. When scanned using a dedicated code reader, barcodes make it possible to quickly transmit key information, such as the price, composition, country of origin and the manufacturer, thus increasing efficiency and accuracy in a range of industrial processes.

Advanced features

The label can be flexible or rigid depending on your requirements and the context.

Customisation of labels, with logos and/or other specific information printed on them.

Attachment options, adhesive or riveting.

Incremental numbering for better stock management and control.

Security and quality for maximum traceability.

The benefits of barcode labels for industry

Barcode labels are a practical, quick and reliable way of identifying, tracking and managing products and raw materials. In the industrial and logistics sectors, they play a vital role for inventories, product traceability and operational efficiency. They help reduce human error, as the products are used or at each point in the supply chain by delivering accurate, real-time information on the labelled products and equipment.

Which barcode label is best for your business?

The type of barcode and the material for the label, whether metal or plastic, is of strategic importance in guaranteeing the traceability of production flows, stock and raw material management. This is a decision that is dependent on the specific requirements of the company, the intended application and the operational context. This means that the environment in which the barcode label will be used, as well as all the technical, chemical and mechanical constraints, must be considered in this choice.

Metal barcode labels are usually best suited for harsher environments and plastic labels are generally adequate for use in indoors settings and/or for short-term requirements.

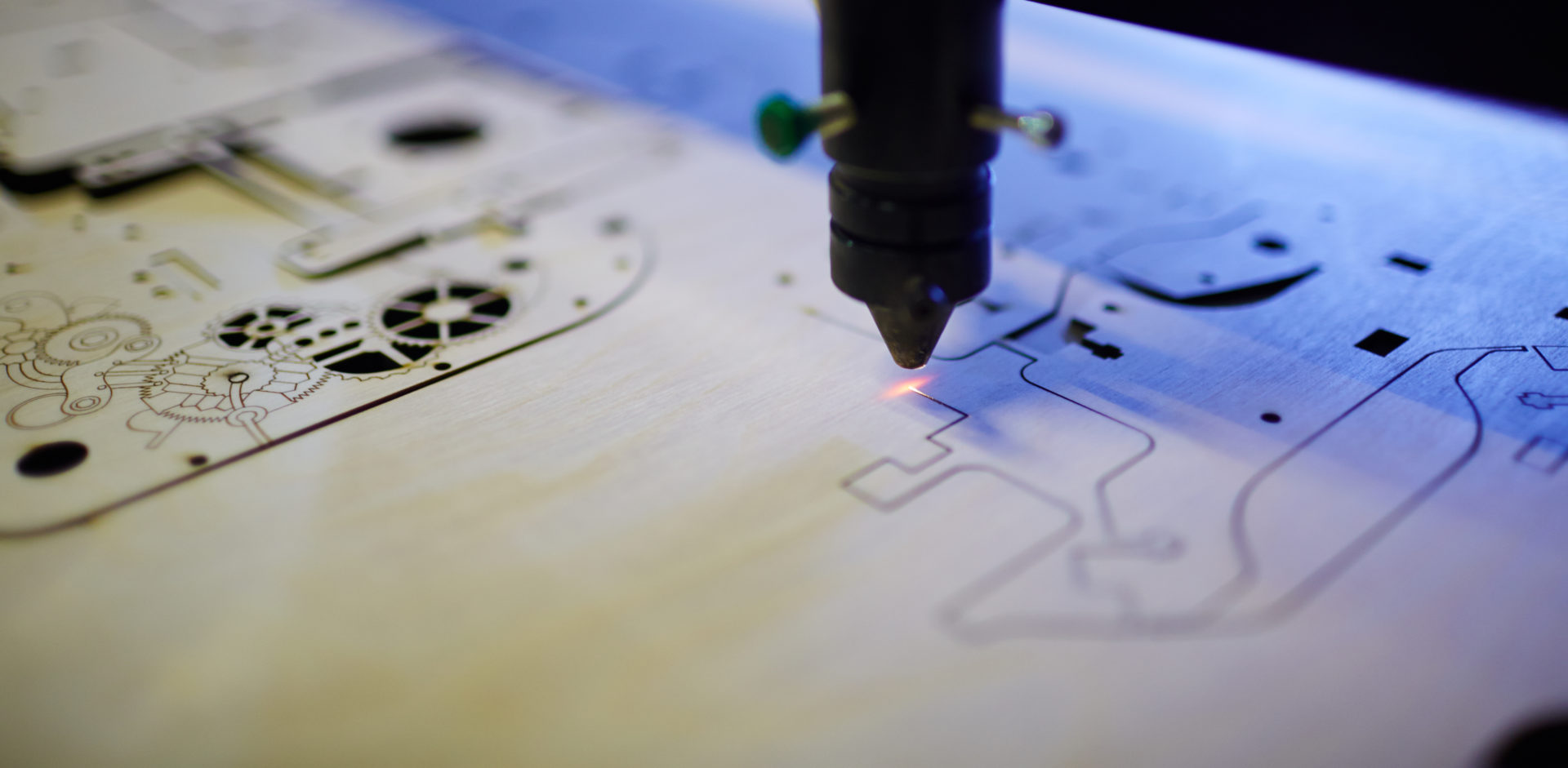

How do we make and print our barcode labels?

The quality promise made by Martin Technologies means a total commitment to excellence at every stage of our production process, from the label design to the marking.

With the wide range of marking methods available (digital printing, chemical engraving, serigraphy, laser engraving, mechanical engraving and anodizing), we can guarantee the precision of the marking on our barcode labels. The advanced technology we use is selected according to the label type and the environmental constraints, thereby guaranteeing the durability and legibility under all these conditions.

Find out more about our barcode labels

For further information, please contact us.

Contact us

Your request concerns